I am a results-driven and highly motivated Process Engineer Professional with a rich background spanning over 17 years in engineering, design, and project management within the oil and gas industry. Throughout my career, I have successfully overseen onshore and offshore oil and gas processing facilities, encompassing all project stages: from conceptualization and feasibility studies to detailed design and execution.

My expertise lies not only in technical proficiency but also in fostering exceptional interpersonal and communication skills. I am a natural team player and have a proven track record of providing effective leadership both during tendering and project execution, ensuring the award and successful delivery of projects on time and within budget.

One of the most rewarding aspects of my journey has been my focus on process development. I have dedicated significant effort to research and analyze new and existing technologies, processing plants, identifying bottlenecks, and conceptualizing innovative solutions. My passion for technology evaluation and selection has played a vital role in implementing new processes that enhance efficiency and add significant value to projects.

Within my career, I have actively engaged in extensive communication with clients, licensors, engineering departments, vendors, and contractors. This interaction has allowed me to build lasting professional relationships and collaborate effectively in diverse, global environments.

I am driven by a relentless pursuit of excellence and a commitment to delivering optimal results in every endeavor. My ability to think innovatively and my strong leadership skills have consistently positioned me as an invaluable asset in driving success for engineering projects within the oil and gas sector.

Resume

/My entire career

5-year full-time MEng in Chemical Engineering, including the following main competencies:

5-year full-time MEng in Chemical Engineering, including the following main competencies:

Familiarity with all process design safety requirements.

Possessing an excellent team spirit and capable of interacting effectively with other discipline engineers.

Comprehensive understanding of government and industry related rules and regulations.

Familiar with CHEMCAD, HYSYS, HAZOP and AUTOCAD.

Extensive experience of developing industrial chemical processes.

Knowledge of both mechanical and instrument engineering.

Able to work in cross-functional projects.

Experience of absorption, evaporation, distillation and electromagnetic equipment.

Able to perform predictive and root cause analysis of problems and then initiate corrective action.

During this assignment in the Asia Pacific region, the main responsibilities of my role were:

Shaping and executing product strategy in line with the core business strategy.

Make recommendations on strategic growth and sustainment strategies pertinent to the Production service line covering Early Production Facilities, MOPUs, and Production Enhancement offerings.

Financial planning for all production-related offerings, its sustainability, and for yearly operating plan goals and budgets.

Generating product portfolio strategies.

Serve as the product expert and provide training and guidance for sales and field service.

During this assignment in the MENA region, the main responsibilities of my role were:

During this assignment in the MENA region, the main responsibilities of my role were:

Starting up a new project management and engineering office in Dubai to support the group in tendering and project activities, including candidate screening, interview, selection and mentoring.

Providing direction and leadership to the Lead Engineers during both tendering and detailed design activities.

Coordinating multi-discipline interfaces to properly address these with resolution of technical issues in a timely manner.

Managing engineering interfaces across the Project Management Team.

During this assignment in the Asia Pacific region, the main responsibilities of my role were:

During this assignment in the Asia Pacific region, the main responsibilities of my role were:

Providing support and expertise to the Project Engineering Team during the conceptual, FEED and execution phase to ensure an integrated solution and design that meets the project’s defined safety, quality, and operability requirements.

Providing cross-discipline coordination of work activities for discipline engineers assigned to the Project’s Engineering Team.

Implementing and executing engineering processes and procedures.

Preparation of company procedures and standards.

Managing engineering interfaces across the Project Management Team.

During this assignment in the Asia Pacific region, the main responsibilities of my role were:

During this assignment in the Asia Pacific region, the main responsibilities of my role were:

Managing a team of engineers responsible for engineering turnkey Early Production Facilities, MOPUs, Topsides and Production Enhancement Systems.

Providing technical support and expertise to existing operational production facilities across the globe.

During this contracting role, I rotated between the Expro UK and PTI Thailand office involved in the design and engineering of a number of Early Production Facilities being supplied to PDVSA. During this time I coordinated a multi-discipline team in the Bangkok Expro PTI office with regular visits to the client offices in Maturin, Venezuela.

The main responsibilities of my role were:

During this contracting role, I rotated between the Expro UK and PTI Thailand office involved in the design and engineering of a number of Early Production Facilities being supplied to PDVSA. During this time I coordinated a multi-discipline team in the Bangkok Expro PTI office with regular visits to the client offices in Maturin, Venezuela.

The main responsibilities of my role were:

Preparation of technical proposals for oil and gas processing facilities, including the development of process design deliverables and the budgeting of capital and operating costs.

Preparation of process engineering deliverables on construction projects and process engineering support to operational production facilities.

Developing high-value process designs with the highest standards of engineering integrity, safety and environmental protection.

Preparation of Hysys, Flarenet and Flaresim simulation reports for oil and gas production facilities.

Managing project interfaces with client and suppliers.

During this role I was responsible for:

During this role I was responsible for:

Generating Process Engineering, Process Simulation and Engineering Drawings like PFDs & P&IDs.

Developing high value process designs with the highest standards of engineering integrity, safety and environmental protection.

Selection and design of correct processes in the project, leading towards optimization in terms of technology, time of implementation and cost.

Preparation of Line Designation Tables, Process Data Sheets, Vessel & Tank Data Sheets, Instrument Data Sheets, Equipment Lists and Technical Offers.

Vessel Sizing, Line Sizing, Blowdown Calculations, Flare Radiation & Gas Dispersion Calculations and PSV Sizing.

Preparation of Cause & Effect Diagrams, Alarm & Trip Setting Lists, Basis of Designs, Functional & Control Logic Descriptions.

This was my first job after finishing my MEng in Chemical Engineering and MSc in Environmental Diagnostics, following my MSc placement for Yorkshire Water. During this role I was responsible for:

This was my first job after finishing my MEng in Chemical Engineering and MSc in Environmental Diagnostics, following my MSc placement for Yorkshire Water. During this role I was responsible for:

Developing methods and carrying out planned experiments in order to assess the performance of potential new technologies for water and wastewater monitoring.

Evaluating data from laboratory experiments and field trials by using mathematical modelling.

Making decisions and recommendations that were recognized as authoritative and had an important impact on extensive engineering activities.

Portfolio

/Major Projects Undertaken

| YEAR | CLIENT | DESCRIPTION |

| 2006 |  |

Desalter Brine Hydrocyclone Packages |

| 2007 |  |

Electrostatic Coalescer Package |

| 2008 |  |

3 Phase Production Separator Packages |

| 2008 |  |

Produced Water Conditioning Package |

| 2009 |  |

Wellhead Desanding Package |

| 2011 |  |

Produced Water Treatment Package |

| 2010 |  |

Produced Water Treatment Package |

| 2010 |  |

Water Injection Plant |

| 2010 |  |

Seawater Anti-Fouling Package |

| 2010 |  |

Seawater Strainer Package |

| 2011 |  |

Burun Field SPP Facility Sand Washing Facility |

| 2011 |  |

Refinery Water Treatment Capacity Expansion Conceptual Study |

| 2011 |  |

Seawater Coarse Filter Packages |

| 2011 |  |

FPSO Separator Desanding Internals |

| 2012 |  |

Hypochlorite Dosing Package |

| 2012 |  |

Deaerator Package |

| 2012 |  |

Skim Pile |

| 2012 |  |

Well Testing Package |

| 2013 |  |

15,000 BPD Early Production Facility |

| 2013 |  |

50,000 BPD Extra Heavy Oil Early Production Facility for PetroIndependencia

|

| 2014 |  |

50,000 BPD Extra Heavy Oil Early Production Facility for PetroJunin

|

| 2014 |  |

50,000 BPD Extra Heavy Oil Early Production Facility for PetroMiranda

|

| 2015 |  |

50,000 BPD Extra Heavy Oil Early Production Facility for PetroSinovensa

|

| 2016 |  |

35 MMSCFD Modular Gas Processing Facility

|

| 2017 |  |

33,000 BPD Partial Processing / Bulk Water Removal Package

|

| 2018 |  |

15,000 BPD Produced Water Compact Flotation Unit

|

| 2018 |  |

33,000 BPD Produced Water Deoiling Hydrocyclone Package

|

| 2018 |  |

Produced Water Compact Flotation Unit Upgrades

|

| 2019 |  |

Ingenium II Switchgear and Control System

|

| 2019 |  |

B80 MOPU Topsides

|

| 2019 |  |

6,000 BPD Seawater Modular Injection System

|

| 2020 |  |

Semi-Automated Well Unloading Unit

|

| 2020 |  |

100,000 BPD Seawater Injection Topside

|

| 2020 |  |

Automated Well Unloading Unit

|

| 2020 |  |

Automated Seawater Modular Injection Unit

|

| 2021 |  |

Pipeline Flushing Package

|

| 2022 |  |

D12 MOPU Topsides

|

| 2023 |  |

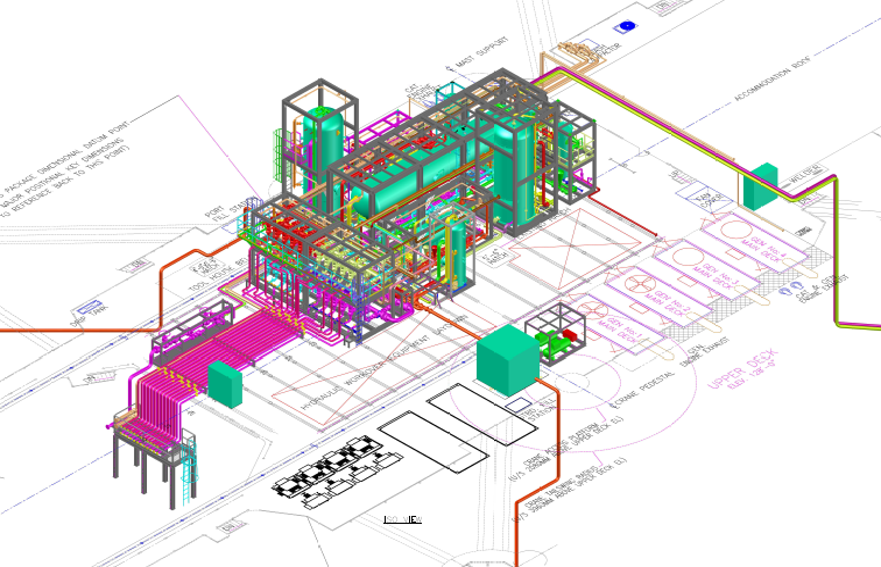

Rossukon Platform Topsides

|

| 2023 |  |

Carbon Neutral Hydrogen Production Facility

|

PDVSA

Early Production FacilityPDVSA

Coastal Energy

MOPU Process PackageCoastal Energy